Auto-braking systems have undergone a series of changes. After the invention of cars, it was not easy for people to bring them to a halt. The first cars applied simple braking systems that were not reliable. For instance, they relied on a simple lever system made of wood that moved against the wheels whenever the driver wanted to bring a moving car to a stand. This type of braking system worked only when the vehicle was moving at a speed of between 10mph to 20mph and where there was sparse traffic (Kinkaid, O’Reilly & Papadopoulos, 2003).

In 1890s, when Michelin brothers made the pneumatic rubber tires, the old wood braking structure was rendered useless since the system of woods used to destroy the rubber badly, and this generated the requirement for a substitute braking system. In the year 1898, one of the inventors from Cleveland made an electric car that had front-wheel disc brakes. This braking system comprised a caliper that had braking pads and a disc that resembled modern bicycle brakes. One of the biggest challenges of this braking system is that since they were made of a copper brake lines that moved against a hard metal disk, they produced a loud screeching noise that could affect people in the car and those around it (Kinkaid, O’Reilly & Papadopoulos, 2003).

This type of braking system was used for about five years before further advancements were made. After this, another scientist named Herbert Frood came up with a solution that aimed at reducing the noise from the braking system. Herbert invented a method of lining the pads with the durable asbestos. After this invention, asbestos was used in the braking system for a long period. Asbestos was used in the braking system up to the early 1980s when safety and health concerns about it were raised. Since then automobile braking systems have undergone a number of changes all of which are aimed at improving the performance of this braking system (Tsunehara et al., 2006). This essay will examine the structure and important parts of the automobile braking systems, its work, the advancements made in the automobile braking systems, and the effects of changing trends in the braking system.

The Structure and Components of an Automobile Braking System

The current automobile braking systems are composed of several components including electronic, mechanical, and hydraulic systems which apply both friction and heating in the process of halting a moving vehicle. Currently, vehicles have braking systems that work on all four wheels of a vehicle. The braking system used may either be a drum or a disk type. The brakes applied in the front wheels of a car play a greater role in stopping it than the rear braking system; the rear braking system transfers much of the car weight to the front wheels (Kinkaid, O’Reilly & Papadopoulos, 2003). Majority of the cars are designed so that the disc brake system is placed at the front, while the drum braking system is located at the rear wheels. In most cases, disc braking systems are used in expensive and high performing cars while the all-drum braking systems are used in cheap and old cars.

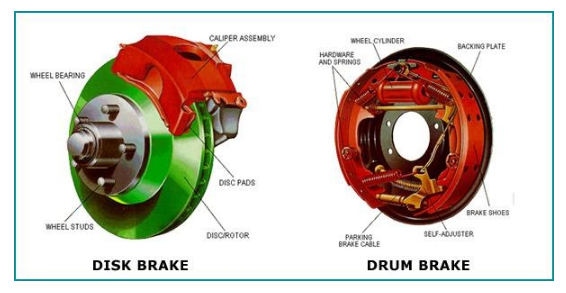

Figure 1. A diagram showing the structure of the disc braking system and the drum braking system.

The disc braking systems contain the caliper assembly, disc pads, wheel bearings, and a disc or a rotor, and the hardware that is used to mount the braking structure on the vehicle. The caliper of the disc braking system is fixed to the master cylinder by using hoses, tubes, and the valves that transfer the brake fluid (Breuer & Bill, 2008). On the other hand, the drum braking system is made of a backing plate, brake shoes, a drum, an axle, and or hub assembly, wheel bearings, the wheel cylinder, and the hardware which is used in fixing it to the vehicle. To improve its performance, the wheel cylinder of the braking system is fixed to the master cylinder using hoses, tubes, valves that transmit the brake fluid to the rest of the braking system. Some of the drum braking systems have double leading shoes with each of them having its hydraulic cylinder, while the others have one trailing and one leading shoe fixed with a pivot at its front. This design enables the two shoes to be separated from each other by a cylinder at its end. Although this system is simple, it is less powerful.

In the automobile braking system, the brake fluid transfers force by using pressure from where it is applied through the hydraulic channels to the rest of the braking mechanisms that are located near the wheels. Since the braking system generates a lot of heat, the brake fluid that is used should have a high boiling point for it to be effective. This braking system only works when the vehicle is under operation. In addition, the braking system is designed in a way to avoid corrosion, but the corrosion inhibitors used in this system depletes with time. One of the problems with this system is the excessive moisture produced when it is in operation (Kinkaid, O’Reilly & Papadopoulos, 2003). Research is being carried out with the aim of identifying the vaporization point that may affect the safety and the efficiency of the automobile braking system.

In addition to the hydraulic braking system, automobiles also have handbrakes that mainly act on two wheels of the vehicle which are mostly the rear ones. This braking system provides limited braking when the hydraulic braking system fails completely, though they are designed as parking brakes. The handbrake has been devised in a way that its lever pulls a cable linked to the brakes by small levers. This braking system is applied by using a ratchet found on the handbrake lever (Breuer & Bill, 2008). A push switch is used to separate the ratchet by freeing the lever on the drum brakes; the handbrake presses the brake linings onto the drums.

The Work of the Braking System

When the driver depresses the pedal, the pressure generated on the brake pedal is transmitted to the piston found in the master cylinder. This, in turn, forces the brake fluid to move from the master cylinder via the brake lines and the hoses to the wheel cylinders and the calipers. The force that is applied to the pedal of the vehicle generates an equivalent force on each of the vehicle’s piston. Wheel cylinders and calipers have pistons that are either fixed to the brake shoe or the disc brake. Each output from every piston pushes the friction solid that is fixed to the wall of the brake drum of the rotor, and this stroke slows down the rotation of each wheel. When the pressure applied to the pedal is released, the shoes and the pads return to their original positions (Breuer & Bill, 2008). This forces the brake fluid to be transmitted back to the master cylinder via the flexible tubing and the hose.

Map Your Success Out!

Attract high grades like a magnet! Time to get on the right side of your professor.

Advancements Made to the Automobile Braking Systems

The automobile industry is working towards the production of integrated braking systems that are not only able to slow down a vehicle but a braking system that can be used for other functions such as capturing the energy and stabilizing it. The automotive braking system is among the most important parts of car systems. The evolution of the braking system is aimed at improving the overall efficiency and safety of the users (Chabot, 2015). One of the challenges that researcher run across in the development process is that it is difficult to separate technologies that have practical applications from those that do not have any practical operations.

The electrification of vehicles and the production of new braking systems will lender the current braking systems obsolete. Some of the expected changes in making the new braking system include: having braking systems that have a zero drag. The current braking system has an inherent caliper drag. This caliper drag reduces the efficiency of the automobile braking system (Chabot, 2015). Hence, the production of braking systems that have zero drag will significantly improve the operation of the braking system.

The other improvement that engineers are working on in the automotive braking system is torque vectoring. This will provide a differential ability to vary the torque power that is delivered to each wheel. In its turn, it will provide improved road handling and grip irrespective of whether the driver is decelerating or accelerating. The system of power transfer has already become common in all-wheel-drive vehicles, all-electric vehicles and it is also used in the electric hybrid vehicles (Chabot, 2015). The invention of torque vectoring necessitates the introduction of an electric monitoring system, in addition to normal mechanical components.

The automobile braking system is also expected to be improved so that it will have faster activation times. The introduction of a responsive torque vectoring and the elimination of the caliper drag have brought about the need for quick-activating parts. For instance, some motor production companies such as the Continental AG have invented new types of brake boosters, which have the ability to offer a short activation time (Chabot, 2015). This is one of the solid improvements that has been achieved due to previous developments used in the automobile braking systems.

Another change that is being implemented towards improving the work of braking systems is the introduction of the regenerative braking system. It is important due to the increased electrification of vehicles. Electric vehicles have enabled the introduction of regenerative braking system that entirely relies on the electric motor-generator (Chabot, 2015). Due to the migration from the kinetic energy recovery system that was relied on in formula one, one of the main concerns that has been raised in regard to this advancement is that it will require the invention of perfect software which will lower its safety.

Electromechanical braking is also another improvement that has been proposed to the automobile braking systems. This braking system is expected to become the dominant braking technology in the future. Majority of the companies that have invested in the production of this type of braking system have each produced a different type of electromechanical braking system.

Step 1. Order Placement

Step 2. Order Payment

Step 3. Paper Downloading

Adaptive cruise control system is another important advancement that has been invented with the aim of improving the operation of the automatic braking systems. This type of braking systems keeps an automatic distance between the cars. It makes driving much easier especially in stop-start driving situations. This system can allow the driver to pre-set the speed range within which the system works (Meyer, 2015). This invention is based on the cruise control system, but it has a radar sensor that has been set to about 200 meters with a beam angle of about 12 degrees. The automatic braking system can detect that the traffic ahead is slowing down and it will adjust its speed to match the speed of the vehicles ahead. This automatic braking system will warn the driver when driving too close to the car that is in front. The automatic braking system does this through sound signals and visuals, which are followed by a short braking jolt, and in extreme cases, it brings the car to a halt. It is achieved by using the front assist system that alerts the brakes whenever it senses the likelihood of a collision.

Challenges Facing Implementation of the New Automobile Braking System

Although there are benefits that the introduction of the new technologies will have in the automobile industry, there are still several hurdles that have slowed down the introduction of these braking systems (Kinkaid, O’Reilly & Papadopoulos, 2003). One of these challenges includes the risk that the technologies have not been fully tested in regard to their safety and reliability when used in different conditions and driving styles.

Another challenge that has slowed down the process of implementing the new inventions in the automobile braking system is the high costs that are required in the process of developing and testing this invention. The new technology needs thorough vetting which also requires time and money. Also, after the inventions are perfected new costs will be required to build new lines for the production of new braking system.

Economies of scale is another factor that has hindered the production, development, and implementation of the invented braking systems. For instance, a small organization Vienna Engineering Company invented and patented a cam-disc braking structure. But the challenge is that this company is small to the Tier One suppliers since it does not have the initial capital and the needed influence for driving its electrochemical invention to the market. This challenge can be solved by using an automaker, merging or partnering with a larger company.

Driving Factors for the Change of Braking Systems

One of the drivers for a change in the braking system is the demand for driver assisted high performance brakes. Also, the invention of driverless cars has increased the need for the change of automobile braking systems. The introduction of the driverless cars has pushed for autonomous braking system which will range from electronically controlled braking systems to electric parking brakes with an auto hold (Meyer, 2015).

Another driving factor for the change of the automobile braking systems is the need to meet emission reduction targets. This has affected the decision about the fuel efficient inventions and systems that allow energy recuperation during braking. Companies are also working on methods to reduce residual drag which allows brakes to function with the start-stop function. Reducing residue drag is important because a reduction by 0.5Nm has a potential of saving up to about 0.1 liters of fuel used for every 100 km traveled (Meyer, 2015). The aim of all automakers is to produce, a lighter, smaller, faster, and more durable braking system. The braking systems that are to be generated need to be affordable.

The need for having an automatic emergency braking system is another driving factor. Companies are working hard towards building sensitive braking systems that can recognize an object and the required stopping time. They also try to develop a system which will bring to a stop a vehicle within a given period. This is important because the brake’s response speed will determine the amount of time available for the installed sensors to analyze the emergency situation. The current braking systems are quick, but they are not quick enough to decelerate big vehicles within the required time to prevent an accident. The current braking system requires optimization of several components starting from the braking control unit, the calipers, to the fluid dynamic of the system (Meyer, 2015). The inventions that have been made may achieve a faster pressure-apply by using conventional electronic stability control.

Conclusion

The auto-braking system has gone through a number of changes since its invention all these changes are aimed at improving its performance and safety. The advancement in the technology has contributed greatly towards the improvement of the automobile braking system. For instance, the production of the automatic braking systems is a huge step towards enhancing the safety of automobile braking systems. The automatic braking systems have been made in a way to sense and avoid an impending collision with an obstacle without any input from the driver. This braking system is made of sensors that include radar, infrared, ultrasonic, and other technologies. Auto-braking systems are comprised of several components such as the mechanical, electronic and the hydraulic systems that use both heating and friction to bring a car to a halt. The braking systems used in cars can be either of a disk or a drum type where the disc braking systems are used for the front wheels while the rear drum braking systems are used for the rear wheels.

The auto-braking systems use a braking fluid in the process of transferring force under pressure after it has been applied through the hydraulic channels to the other mechanisms of the braking systems. Due to the initial challenges that the auto-braking systems faced several changes have been made but some of them have not been implemented due to different problems. For instance, auto-braking systems with a zero drag have been produced. Braking systems with torque vectoring have also been created; this is aimed at improving the grip when the driver is either decelerating or accelerating. The activation time for the braking systems has also been reduced to prevent accidents during emergencies. In addition, automatic braking systems that are fixed with sensors have been invented. This automatic braking system brings a vehicle to stop whenever it approaches an obstacle. Some of the challenges that face the implementation of this inventions include the fact that majority of these inventions have not been tested for their reliability when used in different conditions.

Also, the new technologies require both time and money for their implementation. In spite of all these challenges, it is expected that this invention will be implemented and automobile brakes will range from the automatic emergency brakes to electric brakes with an auto hold.

Don't spend another minute

worrying about deadlines or grades. Have a question? Chat with us!