Chemical Engineering: Factors Affecting Anaerobic Digestion

Over the last century, many researches and developments have been done to facilitate advancement in the field of wastewater treatment techniques. Human usage of wastewater has been increasing, which has led to escalated demand for these treatment applications to clean wastewater and the environment. Current paper focuses on anaerobic digestion. This treatment is a biological application of wastewater that reduces organic content of the wastewater.

Anaerobic digestion in wastewater treatment has two different uses. The first use is that it is a treatment process for primary sewage treatment or organic industrial effluent. The other use is that it is a method of treating the sludge produced by wastewater treatment plants. This is a process of decomposing organic matter of municipal sewage sludge in the absence of oxygen under conditions of suitable operational control. This review paper focuses on different features and applications in anaerobic digestion and pays close attention to the Upward Flow Anaerobic Sludge Blanket, also known as the UASB.

Anaerobic Digestion Stages

Techniques

- Upward Flow Anaerobic Sludge Blanket (UASB)

- Stabilization Ponds

- Other Anaerobic Wastewater Treatment Techniques

Advantages and Disadvantages

Introduction

Wastewater treatment is a process that is applied to effluent to make sure that it meets respective standards of quality before it is released into the environment. The treatment is aimed at improving quality and safety of the waste effluent. Wastewater must be adequately treated to prevent and eliminate the risk of contamination and the likelihood of causing ailments. Wastewater treatment involves application of various technologies aimed at improving or upgrading wastewater quality (Valo, Carrère, & Delgenès, 2004). Generally, the process starts with the collection of wastewater in a central, well-segregated location that is then subjected to various treatments. Wastewater is most of the time produced in large volumes and, therefore, treatment should be carried out on a continuous flow basis (Bolzonella, Pavan, Battistoni, & Cecchi, 2005). Wastewater treatment process depends on various factors, including available resources and nature of the effluent. Effluent is classified as chemical, physical, and biological. The treatment process may sometimes necessitate application of more than one method to achieve desired outcomes. Effluent consisting of different matters may be treated using both anaerobic and aerobic methods. The current paper focuses on the treatment of wastewater using the Upflow Anaerobic Sludge Blanket (UASB).

The UASB is a form of wastewater treatment that uses an anaerobic digester that is methanogenic (methanol producing). Under anaerobic state, there occurs degradation of organic pollutants in the wastewater by microorganisms to produce two gasses, namely methane and carbon dioxide. This degradation is seen to be effective since it produces small amounts of sludge. In addition, it is less costly since the amount of sludge to be disposed of is less as compared to other conventional aerobic processes. In the UASB, wastewater is introduced to the reactor, which is a single-tank process. Wastewater gets in the reactor from the bottom where it flows in an upward direction through a sludge blanket (Bougrier, Delgenes, & Carrere, 2007). The blanket consists of biologically formed particles or granules. Wastewater is treated upon coming into contact with the particles. Microorganisms in the sludge blanket degrade organic components producing methane and carbon dioxide. The UASB reactor behaves like a suspended growth of microorganisms attached to each other as small particles that form granules. These granules become the sludge blanket at the reactor’s bottom.

Map Your Success Out!

Attract high grades like a magnet! Time to get on the right side of your professor.

Gasses produced in the reactor mix with the effluent through agitation in a circular manner to form and maintain the granules. The attached gas and particles rise to the top. Free gas bubbles then drop on the sludge blanket. Released gasses are collected in the gas that comes on the top. Apart from sludge granules formation, there occurs erosion in the bed of the sludge, which exposes the granules to a high mixing intensity (Yang et al., 2006). The re-circulation of gas further provides mechanical mixing that prevents accumulation of biodegradable products in the lower bottom. It also ensures that the substrate and the bacteria are in a good contact.

The UASB treatment process has an advantage over other anaerobic treatment processes as it is simple to assemble and operate. In addition, it is capable of tolerating high hydraulic and organic loading rates (Sreekanth, Sivaramakrishna, Himabindu, & Anjaneyulu, 2009). Development of dense granules allows the UASB to use high volumetric COD filling unlike in other anaerobic processes. This enhances development and quality of the sludge, which has high activity and better-settling characteristics.

UASB operations are influenced by various essential factors such as microbial density, floe diameter, and efficiency of a gas-solid separator. Achieving the best outcomes is always supported by application of appropriate criteria. It is beneficial to select wastewater that is capable of developing self-formation granules (Valo et al., 2004). Design of the reactor should facilitate reduced demand of mechanical agitation to reduce the cost of operation and improve efficiency. It should support an effective startup with minimal COD load and must be capable of handling water containing Ba2+ and Ca2+. Rod-shaped Methanothrix species play an essential role in the formation of granule formation. Finally, a combination of activities of several microbes generates desired results.

Factors Affecting Anaerobic Digestion

The rate of degradation is affected by various factors such as temperatures, pH, substrate, sludge inoculation, organic loading rate, availability of microorganisms, and physiological conditions that determine the rate of microbial growth. Up-Flow Velocity and Hydraulic Retention Time also affect the rate of digestion. Other factors include plant size, engine up-time electricity tariff, engine efficiency, and feedstock mixture (Valo et al., 2004). Degradation initiation can be hastened through introducing leachate from a stabilized bed in what is called a sequenced leach-bed process. The small amount of content from a stabilized bed provides inoculation with a desirable microorganism to the fresh system. Such an opportunity facilitates elimination of degradation barriers such as the lack of right microorganisms to support the process. In addition, it provides a sufficient amount of microorganisms to speed uop the degradation process. However, the degradation process can also be hindered by poor mixing of the content, resulting into a heterogeneous nature of the waste. Having different composition of the waste in different sections means that microorganisms grow differently, depending on conditions in those sections.

Degradation failures can be prevented by ensuring utilization of proven and reputable technologies. Application of the right degradation environment supports the process and facilitates achievement of desirable outcomes. Plant size is determined by the amount of waste to be treated and the financial position (Bolzonella et al., 2005). It is advisable to avoid overfilling or under filling the treatment system. Overfilled waste may outflow during the digestion, while under filling would translate into ineffective utilization of available resources. Application of a weak pump may result in poor mixing of the content, leading to poor degradation of the waste.

Temperature

Different microorganisms perform well under varying temperatures. For instance, psychrophilic microbes perform well under the temperature between 4 and 15 degrees centigrade. Mesophilic optimal temperatures are between 20 and 40 degrees, while thermophilic microbes reach optimal growth between 40 and 70 degrees. Temperatures in the bed influence kinetic formulation, including inhibition constants, rate of specific microbial growth, and half-saturation constant (Bougrier et al., 2007). The UASB reactor attains the best performance at mesophilic temperatures between 30 and 35 degrees. However, treatment of vinasse is achieved at thermophilic conditions, most of the time, at 55 degrees. Reactors must be heated to optimal temperatures to support the digestion process.

Step 1. Order Placement

Step 2. Order Payment

Step 3. Paper Downloading

PH Level

Biogas production involves three bacteria. These are methane producing, hydrolysis, and acid-producing bacteria. Acid producing bacteria tend to do well between 5.0 and 6.0, but can tolerate lower levels. On the contrary, methane-producing bacteria counteract the acid generated by the acid-producing bacteria and thus act as an acid buffer to the system (Kalyuzhnyi, Fedorovich, & Lens, 2006). These bacteria work at a pH level between 6.0 and 8.0. Deviation beyond the range affects their performance and a subsequent outcome of the treatment site. They produce bicarbonate that reacts with the acids produced by acid producers and thus facilitate maintenance of pH between 5.0 and 6.0

Organic Loading Rate (OLR)

The rate of loading organic matter per day determines performance of the reactors. Small loading rate can lead to starvation of microorganisms, resulting in their death and subsequent poor performance. Although very high loading rate encourages fast microbial growth, intoxication can occur because of microbial byproducts. In addition, strong agitation can result in an overflow of the just inoculated sludge (Yang et al., 2006). It is beneficial to manipulate the rate of loading to facilitate operations at 80 percent reduction rate.

Up-Flow Velocity and Hydraulic Retention Time

Up-flow velocity refers to the speed of moving through transverse cross sections. Hydraulic retention is the residential time during which effluent remains in the reactor. Increasing the speed of the up-flow effluent can facilitate reduction of the stagnation film (Sooknah & Wilkie, 2004). Digestion process can be improved by reducing resistance of the mass to improve diffusion into the solid phase. The process promotes degradation of the substrate through encouraging microbial growth. Velocities between 0.1 and 1.4 m.h-1 support the best performance of a reactor. Dispersed particles in the blanket and sludge bed allow gas bubbles to move upwards and wastewater to pass. Although the inlet velocity is usually slow, it is not possible to attain uniformity because of the agitation and granules effects. Gas bubbles generate agitations that influence the residence time distribution (RTD).

Substrate

Although many wastewaters can be treated using a UASB reactors, it is important to ensure that it contains adequate organic matter and nutrients. Wastewater from food manufacturing companies offers effective ingredient in the UASB reactors. In case the provided wastewater lacks sufficient nutrients to support microbial growth, it is advisable to add food into the system to provide the overall performance. For instance, wastewater from chemical production industries may have very little nutrients for the microorganisms’ growth (Valo et al., 2004). The ECP production can be promoted through introducing acidogenic bacteria in the initial stages, particularly when the water does not contain sufficient molecular carbohydrates. These microorganisms generate substrate to support the methanogens.

Sludge Inoculation

Different medium can be used to inoculate the sludge. However, the medium must contain sufficient microbial load and appropriate flora, depending on the effluent being digested (Sooknah & Wilkie, 2004). Granules can effectively digest volatile fatty acids such as butyrate, acetate, and propionate. Mesophilic environment can be classified depending on the predominant acetate substrate digested by the methanogens bacteria, namely sarcina-type, rod-type, and filament-type granules. The microbial lag phase marks initial stages just after the inoculation. Provision of favorable conditions for microbial growth reduces the phase and quickly propels to the exponential phase when the rate of growth increases. Microorganisms have sufficient substrate and little competition. They multiply and form granules to support a high rate of sludge digestion. Gas produced by the microorganisms facilitates agitation and mixing of the content. Agitation ensures that all content is digested. After some time, the bacteria exploit all available substrate and thus attain the stationary phase that is marked with no population changes. The rate of microbial growth equals to that of their death, resulting in no significant changes in the population. Later, accumulation of dead cells and waste products increases, creating an unfavorable environment for microbial activities. Digestion process at this stage is called death phase because it is marked with a reducing population. The number of microorganisms reduces further as the amount of organic matter diminishes.

Anaerobic Digestion Stages

Anaerobic digestion involves conversion of organic matter through biological processes. Organic matters are broken down into carbon dioxide and methane in the absence of oxygen. The process is influenced by several bacteria strains. It is an effective method of reducing the effluent mass within a short period of time (Sooknah & Wilkie, 2004). The anaerobic digestion process has seven stages. They are hydrolysis, sugar and amino acid fermentation, oxidation of the alcohols and fatty acids, oxidation of fatty acids with short chains, generation of acetate, and conversion of acetate into methane. The last stage involves carbon dioxide reduction through the application of hydrogen.

We help students to get better grades regardless of the

complexity of the task. Make our talent and expertise work for you!

Hydrolysis involves breakdown of large organic polymers into smaller constituents that can be easily worked on by the microorganisms. Polymers are broken into simple sugars such as glucose, glucose and lactose, fatty acids, and amino acids that provide energy to the microbial cells. The rate of hydrolysis is usually influenced by the microflora composition and activity in various sections (Bougrier et al., 2007). However, the nature of the substrate determines its availability to the microorganisms. For instance, the constituent and particle sizes of individual particles determine the surface area available to the microorganisms and the rate of digestion. It is beneficial to identify all rate-limiting factors based on their causes and necessary corrective actions. Apart from slow hydrolysis, other factors that hinder the digestion process include inhibitory substances such as ammonia and metals. Properties of the organic matter, including proteins, carbohydrates, and fats, influence the rate of hydrolysis. The process can be divided into enzymatic action of the colonized surfaces and biomass colonization.

Biopolymers degradation generates simpler units such as fatty acids, sugar, and amino acids. These are then fermented into simpler products such as propionate, lactase, ethanol, butyrate, hydrogen, and acetate. High fat and protein substrates come from food industries. They provide rich medium for microbial growth such as proteins, minerals, fat, and lignocellulosic materials. The hydrolysis of these substrates is divided into enzymatic hydrolysis and biomass colonization. Substrate composition influences the amount of generated sulfide and ammonia. For instance, manure obtained from poultry and swine and other materials rich in proteins tend to generate a high amount of ammonia.

Methanogens utilize produced hydrogen and acetate to generate methanol that can then be used as fuel. Large molecules, including volatile fatty acids (VFAs), are catabolised into other compounds that can be utilized by methanogens. Acidogenesis takes effect after hydrolysis and involves biological breakdown of remaining components using fermentative bacteria. Some of the byproducts of this process include carbon dioxide, ammonia, and hydrogen sulfide.

Although some hydrogen (4%) and acetate (20%) are products of the acidogenic fermentation, they are obtained from dehydrogenation and acetogenesis of higher and more volatile fatty acids. Acetogenic bacteria that are Obligate H2-producing can generate hydrogen and acetate from higher fatty acids. The production of hydrogen from acetogens requires much energy and, thus, it is usually hindered. The process can be supported by application of a combination of various hydrogen-producing microbes. Favorable conditions encourage effective decomposition of fatty acids into ammonia and acetate (Bougrier et al., 2007). The process takes place alongside production of lactate and ethanol that are converted into hydrogen and acetate. Clostridium formicoaceticum facilitates conversion of lactate into acetate. In turn, acetogens facilitate conversion of ethanol into hydrogen. Hydrogen low partial pressure is an essential factor in the degradation of ethanol, acetate, and propionate during fermentation of methane. Acetogenesis involves further digestion of simple molecules into acetic acid, hydrogen, and carbon dioxide by acetogens. Later, methanogens work on intermediate products to generate them into water, carbon dioxide, and methane.

C6H12O6 → 3CO2 + 3CH4

Techniques

- The Up-Flow Anaerobic Sludge Blanket (UASB) Reactor

- The need for anaerobic reactors increased in the 1970s when the cost of oil went up, making aerobic treatment expensive for industries.

There are different theories that explain development of granules and depend on factors such as agitation:

Granule Development Theories

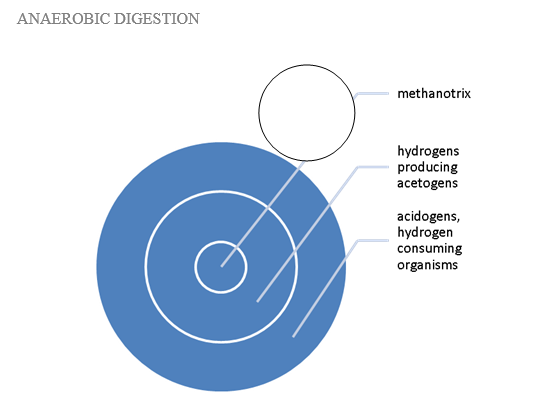

The efficiency of the UASB reactors is usually improved upon formation of anaerobic granules. Development of anaerobic theories has been supported by many other theories. For instance, filters with inert porous media were applied in 1968 to provide microbial attachments. It ensured high retention levels and facilitated fast development of granules. However, the system was superfluous since bacteria immobilized themselves to generate granules. The structure of anaerobic granules has three layers with many heterogeneous micro organizations (Bougrier et al., 2007). It contains all shapes and sizes, including cocci, rods, and filaments with different shapes and sizes. Hydrogen-consuming microorganisms and acidogens are found in large numbers in the intermediate layer. The core that is considered as the third layer contains methanogens. Cavities or holes are evident at the interior contributed by extensive agitations from the vigorous gas production. Anaerobic sludge granulation has three divisions, namely thermodynamic, physical, and microbial.

Figure 1. Showing microorganisms in various granules layers in a UASB reactor

Physical Theories

Physical phenomena realized in the reactor offer an explanation of the granulation process. Some of the key physical theories include selection of pressure, growth, and development of colonized suspended solids. Large particles and granules generate small units that later form other granules. Although some granules are lost through washouts, those that remain grow faster and colonize suspended solids (Bougrier, Delgenes, & Carrère, 2008). Developed granules are strong and cannot be disintegrated by external forces such as liquid circulation, shear forces, and agitation from the generated gas. Selection pressure refers to both gas generation and hydraulic load. Extremely high selection pressure causes removal of the dispersed and light sludge and only retains large particles. The failure hinders generation of a smooth dispersed sludge and concentrates the bacteria growth in a few nuclei. Initial microbial generations are marked with voluminous aggregates. However, they gain density because of the increase in the microbial mass. Selection of an extremely low pressure does not generate good outcomes (Abbasi & Abbasi, 2012). It encourages generation of dispersed biomass marked with poor biogas production and settling characteristics. The biomass tends to float because of reduced density contributed by limited microbial growth.

Microbial Theories

Bacteria produce extracellular polymers (ECP) that facilitate attachment to the granules. Various models associate microorganisms with granulations. They include the Capetown model, Spaghetti theory, and Extracellular polymer (ECP) bonding model. Spaghetti theory is used when handling acidified wastewater. Aggregate structures are formed through attachment of the filamentous methanosaeta (Bougrier et al., 2007). The process is supported with agitations contributed by gas production and availability of a finely dispersed matter. A network is formed from entangled filaments that facilitate trapping of other bacteria. A spaghetti ball is formed as a trapped microorganism multiplies.

Growth of rod-shaped microorganisms facilitates the density increase, resulting in the development of anaerobic granules. The Capetown model makes an assumption that methanol bacterium generates extracellular polymers. Production of these polymers is usually influenced by over-secretion of amino acids, particularly when hydrogen pressure is high. Anaerobic granulation initiates when bacteria, including methanol bacterium, are held in the matrix. Extracellular polymer (ECP) bonding model suggests that the secreted ECP causes changes in the bacteria surface that affects negative charges (Abbasi & Abbasi, 2012). Increasing the organic loading rate facilitates growth of the methanosarcina bacteria, leading to further generation of the ECP and eventual formation of larger clumps.

Thermodynamic Theories

Thermodynamic theories use three models, namely proton translocation-dehydration, multi-valence ion bonding, and four-step model. The multivalence ion-bonding model operates on electrostatic interactions between positively and negatively charged bacteria. Introduction of positively charged ions (such as ferric iron, calcium, magnesium, and aluminum) among negatively charged bacteria facilities the bonding process and subsequent formation of granules (Bougrier et al., 2008). The proton translocation-dehydration model suggests that proton translocation activity facilitates dehydration of the bacterial surface. The theory is explained in four stages, in particular bacterial surface dehydration, formation of the embryonic matter, maturation of granules, and post-maturation process (Abbasi & Abbasi, 2012). This theory explains that acidogenic bacteria supply protons that react with the bacteria’s membrane surface, resulting in dehydration. In turn, the four-step model for granulation takes place in four stages. These are movement of the cell to the substratum, effects of the physiochemical forces, effects of the polymer and microbial attachment, and development of granules from increased multiplication of cells.

Mechanism of Granule Agitation inside a UASB Reactor

Vigorous biogas bubbles and the up-flow velocity facilitate mixing in the reactor. The process creates shear forces and thus facilitates granules’ stability, formation, and structure. Particle-to-particle abrasion and upward flow enable generation of adequate mixing to facilitate an effective digestion process. However, fine biogas bubbles can attach to the granules, causing a rise in the content. Although a long hydraulic retention time (HRT) causes a reduction in the velocity of the liquid, it supports multiplication of the dispersed bacteria (Abbasi & Abbasi, 2012). However, it does not support granule formation. A short hydraulic retention time (HRT) in a reactor with a high up-flow velocity promotes sludge granulation and washout of non-granulated bacteria.

An effective combination of the settling ability and hydraulic stress can facilitate conversion of the flocculent anaerobic into active granular sludge. Maintenance of low temperatures reduces the rate of microbial activity and thus reduces the rate of bubbles generation. The process means that only little agitation is realized that does not influence significant mass transfer between granules and substrate. A slow mixing device placed at the bottom can offer better results though it can be expensive (Abbasi & Abbasi, 2012). Collision between granules facilitates required agitation. The collision process is usually supported by various factors such as the up-flow velocity, trapping of biogas bubbles, as well as settling of biogas and particles inside the granules because of the buoyancy effect. A buoyant particle has densities that almost match those of the carried fluid.

Stabilization Ponds

A waste stabilization pond is a large water body where grey water, fecal sludge, and black water are treated naturally. Wind, solar light, algae, and microorganisms influence treatment processes. These ponds occur in three types. These include facultative, aerobic, and anaerobic. Each type has different design characteristics and methods of treatment. Stabilization ponds are cost-effective and have a high Biochemical Oxygen Demand (BOD) as well as pathogen removal. However, they require large surfaces and expertise due to their design. The effluents produced by stabilization ponds still have nutrients such as nitrogen and phosphorous and thus cannot be released into the surface waters (Abbasi & Abbasi, 2012). They are ideal for the agricultural use.

For effective treatment, stabilization ponds need to be linked in a series of more than three ponds. The effluent is moved from anaerobic section to the facultative one. The anaerobic section becomes the initial (primary) treatment that reduces the amount of the organic matter. The more the pond is deepened, the more the organic matter is reduced. The anaerobic bacteria are involved in converting organic carbon into gasses such as methane. BOD and solids are removed by sedimentation as well as anaerobic digestion (Kalyuzhnyi et al., 2006). In a series of stabilization ponds, the effluent that passes to the anaerobic pond is passed into the facultative pond where the BOD is further removed.

The surface of the pond gains oxygen from wind mixing, natural diffusion, and algae photosynthesis. The bottom layer has no oxygen, thus becoming anaerobic. Solids settle on the bottom and are digested. Both anaerobic and aerobic organisms further reduce the BOD to about 75 percent. It is worth noting that facultative and anaerobic ponds are aimed at removing the BOD, while the aerobic section removes pathogenic organisms. It is usually termed as maturation, finishing, or polishing pond since it is the last section in the series. The pond is designed shallowly to ensure penetration of enough sunlight for effective photosynthesis (Sooknah & Wilkie, 2004). Photosynthetic organisms release oxygen in the water and consume carbon dioxide from bacteria upon respiration.

Other Anaerobic Wastewater Treatment Techniques

The continuous flow stirred-tank reactor (CSTR)

This reactor is also referred to as the back mix or vat reactor. It is applied to predict unit operation variables in a continuous system. It can be used to estimate variables in all fluids and slurries. Its models are approximated using a continuous ideally stirred-tank reactor (CISTR). The method assumes that uniform mixing has been attained and that the composition is identical in all cases. The assumption forms the function of the rate of reaction and residence time. It is beneficial because it simplifies various engineering calculations and offers effective description of research reactors (Kalyuzhnyi et al., 2006). It is worth noting that chemical reactors tend to generate a lot of heat that must be regulated to maintain optimal temperatures for microbial growth. The principle of temperature difference between the reactor and jacketed fluid facilitates transfer of heat to or out of the effluent. In most cases, such transferred fluid is made to flow through the effluent at a high velocity to facilitate a faster heat transfer. A higher rate of heat transfer can be realized when operating with a light effluent. The concentration can be manipulated through the rate of feeding the system to favor heat transfer. Residence time and space velocity affect the rate of heat transfer.

Anaerobic Ponds

Anaerobic ponds mean open basins meant for treatment of effluent in the absence of oxygen. The system allows solids to settle at the base of the pond where the level of oxygen is limited. It is a cheap method of treatment because all parameters are controlled by the nature. Some of the factors that influence the system efficiency include solar radiation, wind action, rainfall, and temperatures (Bougrier, Albasi, Delgenès, & Carrère, 2006). Other influencing physical factors include oxygen, toxic substances, pH, surface areas, underground porosity, and water depth. Although the system is cheap to maintain, it is subject to adverse environmental problems, including topography, high water table, and harmful vectors such as mosquitoes. Such ponds can also become a public nuisance, particularly when placed near residential areas. They generate unpleasant smell and harbor dangerous animals that pose a risk to people living near the location. The nearest housing should be located not less than a kilometer away from the pond.

Although the system has many advantages, it is subject to many limitations. For instance, the system can take much time to attain full efficiency. In addition, it requires a large space away from housing areas. It is not effective for effluent with non-organic matter and pathogenic microorganisms.

Facultative and Maturation Ponds

Facultative ponds mean large, but shallow basins meant for treatment of the sewage through the application of both anaerobic and aerobic processes (Bougrier et al., 2008). Biological and physical processes facilitate complex treatment of the wastewater. Maturation ponds are arranged in a series to facilitate reduction of harmful microorganisms to safe levels. Waste stabilization ponds can be applied only when there is large space. It is an effective method when sewage is suspended to be heavily loaded with pathogens (Bougrier et al., 2006). Installation of anaerobic ponds is done before introduction of the effluent water. Facultative and maturation ponds can reduce the need for a large piece of land.

Waste stabilization ponds are beneficial because they are robust and simple. They also have the potential to handle wastewater flows fluctuations. Three-week retention has the potential to achieve low microbial load that is recommended by the WHO for unrestricted irrigation. A requirement of a large space is a major disadvantage affecting the treatment method. However, the space required depends on the nature of provided sewage. The land must be available for the task over a long period.

Constructed Wetlands (Reed Beds)

They mean engineered wetland systems to treat specific effluent. They can treat agricultural runoff, domestic wastewater, industrial effluent, and storm water. Complex biological, natural, chemical, and physical processes facilitate the digestion process (Razo-Flores, Iniestra-González, Field, Olguin-Lora, & Puig-Grajales, 2003). These include assimilation, sedimentation, adsorption, precipitation, and microbial activity. Some aquatic plants play an essential role in the digestion process, including cattails, phragmites reeds, and bulrushes (Bougrier et al., 2006). These systems are designed to work without a agitation pump and usually work under gravity. Movement of effluent as digestion continues may be either below or above the surface. Above-the-surface movement poses a risk of providing mosquitoes with a bleeding site.

Constructed wetlands can be used when there is a need for a purely anaerobic treatment. They can be used to improve the quality of the effluent that has been treated using other anaerobic methods. They are advantageous because they are relatively cheap and simple in operation and maintenance (Kalyuzhnyi et al., 2006). They are effective for the removal of pathogens and COD/BOD reduction. Some of their indirect benefits include provision of wildlife habitat, as well as a recreational and educational site. Wetlands provide an excellent environment for the growth of crops and trees. However, they require large areas and are relatively more complicated compared with waste stabilization ponds. Attainment of the optimum efficiency can take a long period of time and sometimes even years.

Advantages of the Anaerobic Digestion System

The anaerobic digestion system is cheaper and simpler to operate than aerobic systems. It is meant to handle high-strength wastes such as those containing high percentages of solid matters. It does not consume much energy, making it appropriate for many applications. Some of its advantages include the fact that it is environmentally friendly and can be applied for the treatment of both difficult and ordinary wastes (Yang et al., 2006). Anaerobic treatment systems have a wide range of applications in different places, including industrial and domestic treatment plants. Unlike aerobic systems, anaerobic treatment systems generate biogas that can be trapped and used as fuel. The system can work without additional heating systems in hot regions since it requires mesophilic conditions.

Anaerobic digesters find wide application and offer many benefits. For instance, they can be used for the treatment of waste fibrous material, including manure, wood, and other organic matter. They have the potential to convert the waste into biogas consisting of carbon dioxide, methane, and ammonia. All these products are beneficial and can be applied in other areas. For instance, methane is a good source of electricity. The remaining residue can be used as a source of land nutrients, cow bedding, and compost.

Disadvantages of the Anaerobic Digestion System

Although these systems are effective in the elimination of organic matter, they are inappropriate for the treatment of non-organic matter in the sludge. Some of the challenging non-organic matters include pathogenic microorganisms and nutrients. Various treatment systems like the CSTR, the UASBs, anaerobic ponds, and filters have limited capabilities of removing pollutants and pathogens (Kalyuzhnyi et al., 2006). In addition, the initial cost of constructing the system is high with account for its structure. It also requires highly skilled operators to run and maintain all operations. Some of the operators’ roles include roughing treatment of the industrial and municipality sewage. In addition, the anaerobic system requires much time to start the digestion process. It may also require introduction of alkali to regulate the Ph. In some cases, it may become susceptible to various toxic substances.

Conclusion

The Upward Flow Anaerobic Sludge Blanket is an effective method of wastewater treatment due to various reasons. It is evident that the world population is increasing, thus reducing availability of empty spaces that can be applied for aerobic and ponds treatment methods. Korea is among many countries that have prohibited land filling and ocean dumping of untreated wastes from industries. Disposal of such wastes can result in massive damages to the environment and become a source of various ailments. The Upward Flow Anaerobic Sludge Blanket is an effective method of treatment for different wastes that generates beneficial products. Residues such as carbonaceous materials contain a significant amount of phosphorous and nitrogen that can be applied to enrich the soil for better agricultural activities. Anaerobic conversion of organic matters offers an environmentally and economically attractive alternative that is beneficial to the society.

The UASB is a particularly attractive alternative in hot areas because it operates with mesophilic microbes that can do under those conditions without any need for additional heating. The best results are realized through mass balancing of microorganisms whereby the substrate is enhanced. Provision of required conditions makes it possible to achieve expected results within a short period of time. In addition, the UASB does not degrade the environment since it does not release harmful gasses into the environment. Efficiency of the upward flow anaerobic sludge blanket depends on various factors, including acidity, organic loading rate, and temperature. Other factors are loading rate, agitation, substrate sludge, and inoculation.

Don't spend another minute

worrying about deadlines or grades. Have a question? Chat with us!